High Frequency Induction Heating Pipe Preheating Bending Machine

Guangyuan as induction heating machine manufacture which found in

2000.Over these years we had develop the reliable quality

products.Products divide high frequency,medium frequency,super

audio frequency,ultrahigh frequency.In order to fit customer

requirement,we had produce special input voltage products,such as

three phase 110V,220V,450V,480V.Also now good have further

step,design full automated system,such as melting furnace,forging

furnace,hardening fixture and so on.

Our induction heating machine better performance at hot forging,

hardening,heat-treatment,brazing,bending,melting,annealing,shrink

fitting and so on.

| Model | GY-05A | GY-15A | GY-15AB | GY-25A | GY-25AB | GY-30AB | GY-40AB | GY-60AB | GY-70AB |

| Work Power | 220V 50HZ Single Phrase | 340V~520V 3Phrase 50~60HZ |

| Output Power | 5KW | 15KW | 15KW | 25KW | 25KW | 30KW | 40KW | 60KW | 70KW |

| Input Current | 32A | 32A | 32A | 24A | 24A | 28A | 41A | 52A | 64A |

| Output Current | 100~500A | 200~600A | 200~600A | 200~1200A | 200~1200A | 300~1500A | 400~1800A | 400~2400A | 400~3200A |

| Cooling Water Flow | 0.06-0.12Mpa 7.5L/Min | 0.08-0.16Mpa 7.6L/Min |

| Work Frequency | 30~100KHZ |

| Timing Setting | 1~99S |

| water temperature protection point | 40C |

| Dimension | Main Machine | 530x195x450mm | 570x230x450mm | 530x225x450mm | 570x230x510mm | 550x225x480mm | 640x260x520 mm | 620x250x530mm | 640x280x550 mm | 780x370x620 mm |

| Transformer | | | 370x210x370mm | | 350x215x380mm | 440x260x410 mm | 480x260x410 mm | 510x260x410 mm | 870x430x750 mm |

| Weight | Main Machine | 21.5KG | 27.5KG | 18kgs | 31kgs | 21.5 kgs | 26.5 kgs | 34.5kgs | 37.5 kgs | 54 kgs |

| Transformer | | | 15kgs | | 17 kgs | 20.5 kgs | 31.5kgs | 32.5 kgs | 76.5 kgs |

Delivery Time: within 3 workdays.

Shipping Term:By sea,By air,by express.

Extra accessories accept choose

1>Chiller

2>Customer design Coil

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace,Melting Furnace,Hardening Fixture

Induction heating allows the targeted heating of an applicable item

for applications including surface hardening, melting, brazing and

soldering and heating to fit. Iron and its alloys respond best to

induction heating, due to their ferromagnetic nature. Eddy currents

can, however, be generated in any conductor, and magnetic

hysteresis can occur in any magnetic material. Induction heating

has been used to heat liquid conductors (such as molten metals) and

also gaseous conductors. Induction heating is often used to heat

graphite crucibles (containing other materials) and is used

extensively in the semiconductor industry for the heating of

silicon and other semiconductors. Utility frequency (50/60 Hz)

induction heating is used for many lower-cost industrial

applications as inverters are not required.

Scope of induction heating application

Hardening: gear inner hole harden, screw partial harden, bearing harden, gear

harden

Smelting: precious metal smelting, nanocrystalline smelting molding,

aluminum alloy smelting, silver bead smelting

Welding: stainless steel accessories welding, jewelry welding, copper and

stainless steel welding, handicraft welding

Annealing: stainless steel tableware annealing, special-shaped hollow pipe

fittings,stainless steel tube annealing, stainless steel sink

annealing

Hot forging: hardware heating hot forging, bar forging, steel billet forging,

steel bard head heating

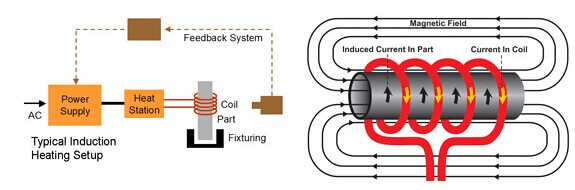

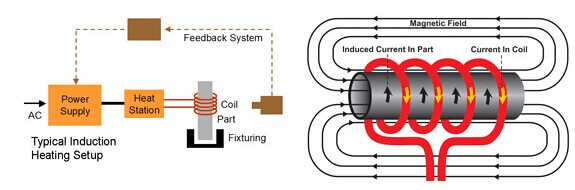

Induction Heating Work Principle

Induction Heating Machine After service

Q1, what is your application?

For example: induction brazing/ billets forging heating/ heat

treatment/ melting furnace

Q2, what is the workpiece metal material/ dimention?

Forexample:steel/stainless steel/brass/copper/Aluminum,etc

diameter, length, thickness, heating zone length, heat treatment

layer depth

Q3, What is the request heating temperature and time?

For example: heating temperature 1000C, 500kgs/hour

Q4, Does your company work on OEM?

Yes, we have a professional design and technical team to do the

customization

Q5, What’s the delivery time after the order is placed?

We arrange the shipment in 3-15 days for standard machine. It takes

us more days for customized machines

Q6, How about the warranty?

The warranty is one year by offering spare parts for free and we

provide lifelong maintenance.

Q7, What can you provide after service?

We provide machine running video, instruction manual in English,

spare parts Also

our engineers are available to clients’ factory and technical

training.

CALENTAMIENTO P/INDUCCION,HORNO DE INDUCCION,MAQUINA DE CALENTAMIENTO

LOS DEMAS APARATOS PARA TRATAMIENTO TERMICO DE MATERIAS POR

INDUCCION O PERDIDAS DIELECTRICAS